Learn how to build a homemade DIY hydraulic press for your workshop. Step-by-step guide for making a powerful tool at a fraction of the cost. Building a 20-ton hydraulic press can seem like a daunting task, but with the right instructions and insights, it can be an incredibly rewarding DIY project. Whether you're a seasoned DIY enthusiast or a beginner looking to expand your workshop capabilities, this guide will walk you through building a robust and versatile hydraulic press.

What Will I Get Out of This?

After reading this guide, you'll understand how to construct a 20-ton hydraulic press from scratch. This tool is indispensable for metalwork, including pressing ball joints, suspension bushings, or even modifying leaf springs for automotive projects.

Materials Needed

- 20-foot length of 5-inch channel iron: This will form the main frame of your press. The channel iron provides the necessary strength and rigidity.

- Manual or air-over-hydraulic 20-ton bottle jack: Starting with a manual is fine, but consider upgrading for ease of use.

- 2-inch by 2-inch quarter wall square tubing: For the press arms.

- Cold-rolled steel, machined for tool holder: Essential for custom pressing tools.

- ¾-inch bolts: Used for pinning movable parts.

- Half-inch steel plates: For the base and press head.

- Additional materials: Wheels for portability, springs or eye bolts for jack retraction, angle iron for the base reinforcement.

Step-by-Step Construction

- Frame Assembly Begin by cutting your 5-inch channel iron to size; you'll need a base, two sides, and a top. Assemble into a rectangular frame, ensuring it's perfectly square. Welding is the recommended method for assembly. Rigidity in the top section is crucial, as this is where pressing happens.

- Base Reinforcement Add wheels to your base for mobility. Strengthen the base with cross-beams or angle iron to prevent tipping. While the base doesn't need as much rigidity as the top, stability is key.

- Installing the Jack Initially, you might opt for a manual bottle jack, which is entirely adequate. Mount this at the top of your frame. For an upgrade, consider an air-over-hydraulic jack. This will require additional modifications, such as mounting brackets and an air supply line.

- Building the Press Arm Use the 2-inch square tubing for the press arm, ensuring it has sufficient length to handle your typical projects. Attach the tool holder and adjustable pins for flexibility.

- Building Press Tools and Accessories Fabricate various pressing tools from scrap materials and steel. This repertoire allows for versatility in the projects you can handle. These tools can be as simple as modified bushing sleeves or as complex as custom-formed metal pieces for specific tasks.

- Drilling and Assembly Precise drilling is required for the pin holes in the frame and press arm. Use a center punch for accuracy, and consider a pilot hole to guide larger bits. Adjustments may be necessary for perfect alignment.

Troubleshooting and Optimization

- Rigidity Concerns: If you notice flexing, reinforce the frame, especially around the top.

- Jack Upgrades: Moving to an air-over-hydraulic system adds complexity but greatly improves ease of use.

- Tool Improvisation: Don't be afraid to modify existing tools or make bespoke ones for specific tasks.

The "Why" Behind the Steps

Understanding the rationale for specific materials and configurations is vital. The choice of channel iron, for instance, balances cost with the strength required to withstand high pressure. Similarly, the decision to upgrade the jack is driven by the need for efficiency and physical ease during repetitive tasks.

Video Tutorial

For those who prefer a visual demonstration, watch a detailed tutorial on building a 20-ton hydraulic press by ThatShopTeacherGuy on YouTube.

This video complements our written guide, providing a clear, step-by-step visual walkthrough of the construction process.

Building a 20-ton hydraulic press is tough but worth it. Save money, gain a versatile tool, ensure safety gear, and customize as needed.

Real-World Applications of DIY Hydraulic Press

A DIY hydraulic press can be a versatile tool in your workshop, offering a range of applications that can simplify and enhance various projects. Here are some practical ways you can use your hydraulic press:

Metalworking and Crafting

- Bending: Shape metal sheets into desired angles or curves with precision.

- Punching: Build clean holes in metal sheets for assembly or design purposes.

- Forging: Forge metal parts into specific shapes, ideal for custom hardware or artistic metalwork.

Everyday Solutions

- Crushing: Compress and crush materials for recycling or waste reduction.

- Cocoa Processing: Extract fat-free cocoa powder by pressing cocoa beans, useful for homemade chocolate making.

- Sword Making: Compress sheets of metal together in the process of crafting blades.

These applications demonstrate the hydraulic press's ability to handle tasks ranging from industrial manufacturing to creative hobbies.

FAQs About Hydraulic Press

When working with a hydraulic press, it's natural to have questions. Here are answers to some common queries:

How much force can a hydraulic press generate?

- The force can vary widely, with some presses exerting just a few tons while others can manage thousands of tons.

Are hydraulic presses safe to operate?

- Yes, when used correctly and with proper safety measures in place, they are safe. Always follow the manufacturer's guidelines and wear appropriate safety gear.

Can hydraulic presses handle different types of materials?

- Absolutely. Hydraulic presses can work with a variety of materials, including metals, plastics, and composites.

How often should hydraulic press maintenance be performed?

- Regular maintenance is crucial. Check the manufacturer's recommendations for specific intervals, but generally, a monthly inspection is a good practice.

15 DIY Hydraulic Press Ideas and Inspirations

Explore 15 creative DIY hydraulic press ideas for your projects. Get inspired to build your own hydraulic press with these innovative designs.

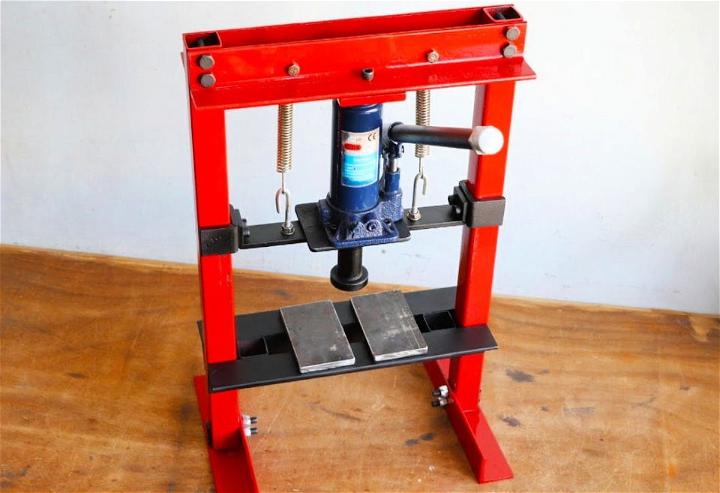

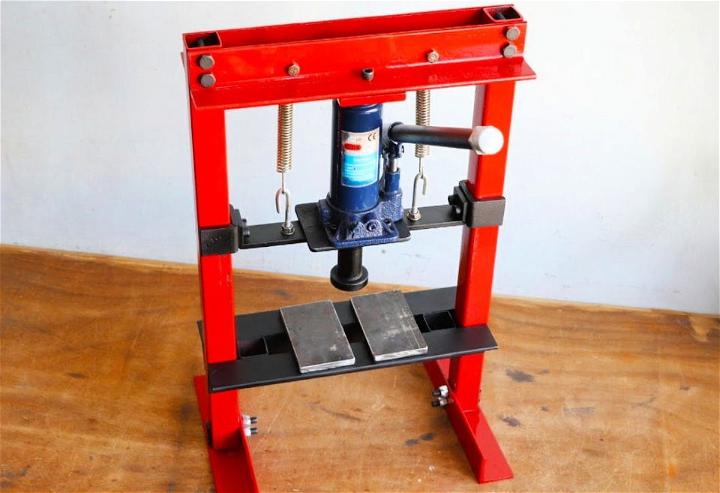

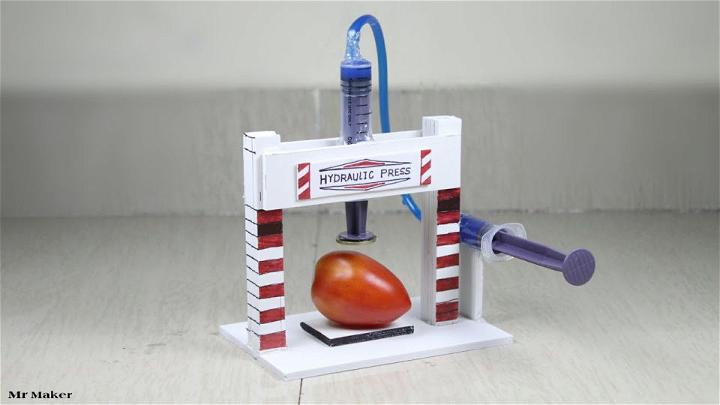

1. Homemade Mini Hydraulic Press Machine

A homemade mini hydraulic press machine can be a real game-changer in your workshop. Ideal for small pressing tasks, its compact design saves space while still delivering the strength needed for tasks like forming jewelry or working on electronics. Plus, the joy of building it yourself adds a personal touch to your tool collection.

2. DIY 30tonne Hydraulic Press

Making a DIY 30-tonne Hydraulic Press might sound daunting, but it's an exciting project for any DIY enthusiast. This powerhouse lets you tackle larger projects, including forging and molding. Its high capacity ensures you can work on diverse projects, from car repairs to crafting custom knives.

3. How to Make a Hydraulic Press

When you learn How to Make a Hydraulic Press, you unlock a world of possibilities. Customizable to your needs, whether it's for pressing flowers or metalwork, it provides a satisfying blend of power and precision. Handy and reliable, it becomes a cornerstone of your creative projects.

4. Building a 16 Tons Hydraulic Press

Building a 16 Tons Hydraulic Press may seem like a hefty endeavor, but it's manageable with the right plans. Perfect for intermediate workshops, this press offers substantial force for bending or shaping metal without compromising space. It strikes a balance between industrial strength and home workshop manageability.

5. Portable Hydraulic Press without Welding

A Portable Hydraulic Press without Welding is your go-to for quick fixes and mobile projects. Its unique design allows for assembly without permanent joins, meaning you can set it up anywhere. Perfect for those who need a versatile tool but might not have a permanent workshop space.

6. DIY Bench Top Hydraulic Press

A DIY Bench Top Hydraulic Press is a marvel of efficiency, fitting neatly on your workbench. It's great for pressing bearings, shaping metal, or even small-scale forge work. Its compact design doesn't sacrifice power, making it a valuable addition to any maker's arsenal.

7. Built a Bottle Jack Hydraulic Press

Building a Bottle Jack Hydraulic Press is a clever way to get hydraulic power on a budget. Using a readily available bottle jack, you can make a press that's both effective and economical. It's perfect for hobbyists or anyone starting their journey into metalworking or other press-needing crafts.

8. Simple DIY 32t Hydraulic Press

Making a Simple DIY 32t Hydraulic Press puts formidable force at your fingertips. Ideal for those requiring extra power for tasks like straightening axles or pressing bearings. While it's a step up in complexity, the reward is a machine that can take on nearly anything you throw at it.

9. Free Hydraulic Press Machine Plan

A Free Hydraulic Press Machine Plan can be your first stop on the journey to building a custom press. These plans provide a foundation, which you can adapt to fit your specific needs and space. They demystify the process, making hydraulic press projects approachable for all skill levels.

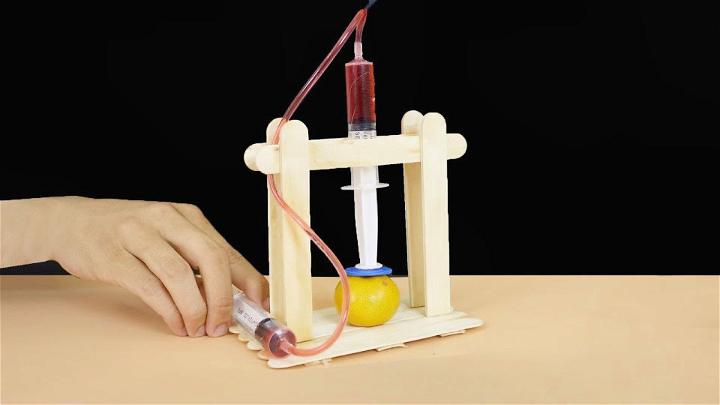

10. Small Hydraulic Press Machine

A Small Hydraulic Press Machine is perfect when space and resource are at a premium. Despite its diminutive size, it delivers enough power for tasks like crafting jewelry or small metal parts. It's also an excellent educational tool for explaining hydraulic principles in a tangible way.

11. DIY Hydraulic Shop Press

Embarking on a DIY Hydraulic Shop Press project elevates your workshop capabilities tenfold. Tailored to fit your space and power needs, this addition means you're ready to take on more demanding projects. From automotive repairs to metal artistry, the possibilities are endless.

12. How to Make Hydraulic Press at Home

Discovering How to Make Hydraulic Press at Home empowers you to add a versatile tool to your DIY repertoire. It's not just about saving money; it's about crafting a machine that fits your specific needs, whether for small-scale metalwork, pressing bearings, or embossing leather.

13. Making an Electric Hydraulic Press

Making an Electric Hydraulic Press combines traditional pressing power with modern convenience. Suited for tasks needing precise control and steady power, it's a workhorse for the modern maker. Also, the electric aspect makes it a plug-and-play solution for workshops with varying projects.

14. Cheap and Easy DIY Hydraulic Press

A Cheap and Easy DIY Hydraulic Press demonstrates that building powerful tools doesn't have to break the bank. With a focus on using accessible materials and straightforward construction techniques, this project lets anyone tap into the usefulness of a hydraulic press without the hefty cost.

15. Bearing Press Out of Bolt and Nuts

Building a Bearing Press Out of Bolt and Nuts proves that sometimes, simplicity is key. This ingenious solution is perfect for solving specific problems like replacing bearings or small pressing tasks. It's a testament to the idea that a useful tool doesn't have to be complicated or expensive.

Conclusion:

In conclusion, building a homemade DIY hydraulic press can be a practical and cost-effective solution for various projects. By following the steps outlined in this article, you can customize your press to suit your specific needs while saving money. From metalworking to jewelry-making, a homemade hydraulic press offers versatility and efficiency for a wide range of tasks. Start your project today and experience the benefits firsthand!