Building a hydraulic log splitter from scratch is a rewarding project that can simplify the process of splitting wood for your fireplace, wood-burning stove, or any woodworking projects. Using a hydraulic car jack and scrap metals, this guide will walk you through building a highly effective and powerful hydraulic log splitter that can make easy work of even the largest logs. Let's start this journey towards building a homemade yet robust log splitter.

Materials and Tools Needed:

- 5-ton hydraulic car jack

- Various pieces of scrap metal (for frame and splitting blade)

- Welder and welding safety gear

- Angle grinder

- Drill and drill bits

- Metal-cutting saw

- Measuring tape

- Safety goggles and gloves

Step by Step Instructions

Learn to build a homemade DIY log splitter with our guide. From materials and step-by-step instructions to safety tips, start splitting logs efficiently.

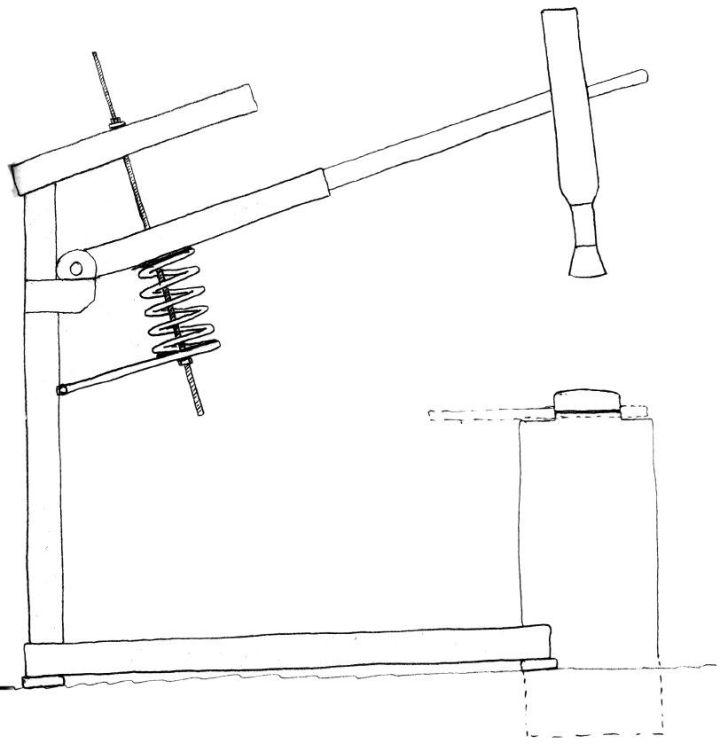

Step 1: Designing Your Log Splitter

Before you begin, it's crucial to have a design plan. Consider the size of the logs you intend to split and ensure the frame you build can accommodate them. The design needs to include a sturdy base to hold the hydraulic jack and a vertical frame to guide the log towards the splitting blade.

Step 2: Building the Frame

Start by cutting the scrap metal to the necessary lengths for your frame. Using a welder, assemble these pieces into a stable base and vertical structure. Ensure the frame is robust enough to withstand the force exerted by the hydraulic jack during the log splitting process.

Step 3: Installing the Hydraulic Jack

Place the 5-ton hydraulic car jack at the base of the frame. Secure it in place, ensuring it's perfectly aligned with the frame's vertical component. This alignment is crucial for efficient log splitting.

Step 4: Crafting the Splitting Blade

Using a piece of scrap metal, fashion a sharp blade that will be responsible for splitting the logs. The blade should be thick enough to withstand the pressure without bending. Weld this blade securely to the lower end of the vertical frame, positioned so that it aligns with the jack.

Step 5: Assembly and Testing

Once the frame, hydraulic jack, and blade are in place, your log splitter is essentially ready. Give all the welds and components a thorough inspection to ensure everything is secure. For safety, always wear protective gear when operating the machine. Test the log splitter with a small log to confirm everything is functioning as expected.

Tips for Safe and Effective Use:

- Always operate the log splitter on stable, level ground.

- Wear protective gloves and goggles when using the splitter.

- Never place your hands near the splitting blade when the machine is in use.

- Regularly check all components for wear and tear, ensuring the log splitter is in good condition.

Video Tutorial

For a step-by-step video tutorial on making this hydraulic log splitter, watch the detailed guide on Diamleon Diy Builds YouTube channel.

It pairs well with this written guide, shining a light on the intricacies of assembling a powerful log splitter with everyday tools and materials.

FAQs About DIY Log Splitters

Get answers to all your FAQs about DIY log splitters. Learn how to build, operate, and maintain your own log splitter with expert tips and advice.

What materials do I need to build a DIY log splitter?

To construct a basic log splitter, you'll need a sturdy frame, a hydraulic cylinder (at least 4 inches in diameter), an engine (5 horsepower or more), a sharp cutting wedge, a hydraulic pump, and pipes that can withstand high pressure (at least 2500 PSI). Don't forget a relief valve for safety to prevent pressure buildup.

How does a hydraulic log splitter work?

A hydraulic log splitter uses a motor to power a hydraulic pump, which builds pressure that drives a cylinder. This cylinder pushes the log against a sharp wedge, effectively splitting it. It's a system that saves time and energy compared to manual splitting.

Can I build a log splitter from scrap materials?

Yes, you can build a log splitter using scrap materials. Many DIY enthusiasts build effective log splitters from parts found in hardware stores, junk lots, or even items they already have. However, ensure all parts, especially the blade and hydraulic components, are safe and functional.

What safety precautions should I take when using a log splitter?

Always wear protective gear, including gloves and safety glasses. Ensure all safety guards are in place, and never place your hands near the moving parts or blade. It's also important to operate the splitter on stable, level ground to prevent accidents.

How can I maintain my DIY log splitter?

Regular maintenance includes checking for hydraulic leaks, ensuring all bolts are tight, and sharpening the wedge as needed. It's also crucial to change the hydraulic fluid periodically and store the splitter in a dry place to prevent rust.

20 Homemade DIY Log Splitter Plans

Discover 20 DIY log splitter plans to make splitting wood easier and more efficient. Save money with these homemade projects for your firewood needs.

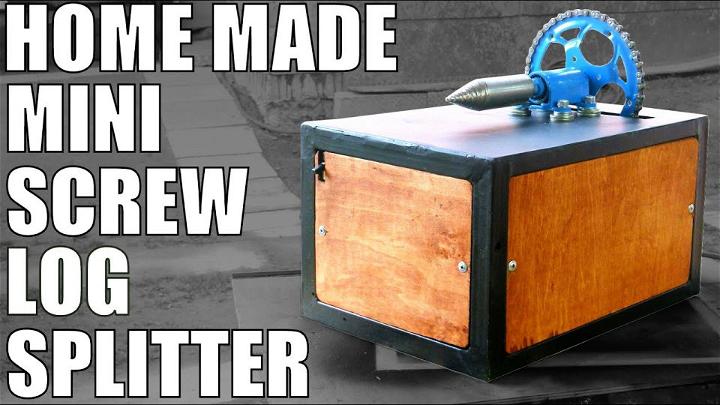

1. DIY Screw Log Splitter

Embarking on building a screw log splitter offers a rewarding endeavor. Its straightforward design ensures seamless wood splitting, suitable for home firewood needs, making it both efficient and user-friendly.

2. How to Build a Small Log Splitter

Designing a small log splitter tackles storage and maneuverability beautifully. Perfect for occasional use, it provides sufficient power for moderate tasks, ensuring practicality and convenience in your backyard.

3. Unicorn Log Splitter Building Plan

The whimsically named Unicorn log splitter marries efficiency with simplicity in design. Ideal for those seeking a reliable, yet unique, machining project, it promises to turn heads while capably managing log splitting duties.

4. Homemade DIY Log Splitter with Loading Arm

Adding a loading arm to a log splitter elevates the functionality, significantly reducing physical strain. This feature streamlines the splitting process, ensuring greater productivity and comfort during extensive wood processing sessions.

5. How to Make a Kindling Splitter

Making a kindling splitter is an approachable project that significantly enhances fire preparation. It provides a safe and effective method to produce small fire starters, making it an essential tool for any fireplace or wood stove owner.

6. Build a Scrap Yard Log Splitter

Utilizing material from a scrap yard to construct a log splitter not only promotes recycling but also offers a cost-effective solution. This project challenges creativity while producing a durable and functional piece of equipment.

7. DIY Foot Operated Log Splitter

A foot-operated log splitter introduces a hands-free approach to wood splitting. It amplifies safety and efficiency, allowing for precise control and reducing the physical effort traditionally required in splitting logs.

8. Heavy Duty Log Splitter

Investing time in building a heavy-duty log splitter prepares you for the most demanding tasks. Its robust design and powerful performance make it indispensable for large-scale wood processing, ensuring reliability and longevity.

9. DIY Manual Log Splitter

Making a manual log splitter embodies simplicity and effectiveness. This project is perfect for DIY enthusiasts seeking a straightforward and economical solution to split logs, offering a satisfying and tangible outcome.

10. Homemade Log Splitter

Fabricating a homemade log splitter from scratch provides a fulfilling project with practical benefits. Tailored to personal specifications, it meets specific wood processing needs while fostering a sense of accomplishment in building a valuable tool.

11. Log Splitter Out of Scrap Metal

Turning scrap metal into a log splitter isn't just resourceful, it's eco-friendly! This approach allows you to repurpose materials, minimize waste, and enjoy the pride of building a useful tool. Its unique design can tackle your wood-splitting needs while showcasing your commitment to sustainability.

12. DIY Hydraulic Log Splitter

A DIY hydraulic log splitter allows for efficient wood splitting with less effort. By harnessing hydraulic power, you can split logs more quickly compared to manual methods. This project affords you the satisfaction of crafting your own tool, tailored to your specific needs and preferences.

13. Log Splitter Out of Reclaimed Rebar

Making a log splitter from reclaimed rebar is both an innovative and eco-conscious choice. This method not only gives old rebar a new life but also ensures your log splitting task is done efficiently. Its rugged design guarantees durability, making it a smart, long-term investment.

14. DIY Log Splitter

Building your own log splitter offers a tailored experience to suit your firewood needs. It's a hands-on project that can bring significant cost savings and a sense of achievement. Plus, customizing it means you can ensure it's the perfect fit for your backyard operations.

15. Amazing Homemade Wood Log Splitter

An amazing homemade wood log splitter can transform the tedious task of splitting logs into a more manageable and even enjoyable one. This project taps into your DIY skills and creativity, leading to a highly efficient and personally customized tool that takes pride of place in your toolshed.

16. Build Your Own Kinetic Log Splitter

A kinetic log splitter operates on immense speed and force, making wood splitting astonishingly quick and effortless. Building your own means you can harness this innovative technology with a personal touch, ensuring you have a robust tool that's tailored to the sizes and types of logs you frequently handle.

17. Cheap Log Splitter with 4 Blades

Introducing a quad-bladed log splitter into your toolkit is a game-changer. Not only does it increase efficiency by splitting logs into four pieces at once, but doing so on a budget makes it exceptionally rewarding. This cost-effective solution doesn't compromise on performance, offering great value for money.

18. Make Your Own Log Splitter

Making your own log splitter from scratch is a fulfilling project for any DIY enthusiast. It allows for a high degree of customization, ensuring you can match it perfectly to your wood splitting needs, whether you prefer manual or powered mechanisms. Plus, it's a great way to sharpen your building skills.

19. DIY Battery Powerd Log Splitter

A battery-powered log splitter brings portability and convenience to your log splitting activities. Building one yourself integrates green energy into your arsenal, allowing for quiet, efficient, and emissions-free operation. This project is perfect for those looking to combine their love for the environment with practical, everyday tasks.

20. Mini Screw Log Splitter

A mini screw log splitter is an innovative tool, perfect for small-scale tasks. Its compact design makes it easy to store and maneuver, ideal for those with limited space. Building one offers a unique project that taps into both your creativity and practical needs, ensuring a satisfying outcome.

Conclusion:

In conclusion, building a homemade DIY log splitter can be a rewarding project for any handy individual. By following the steps outlined in this guide, you can save money and customize your log splitter to suit your specific needs. Remember to prioritize safety, gather the necessary materials, and take your time to ensure a successful and efficient log-splitting experience.