Building an engine hoist, also known as an engine lift, is a rewarding DIY project that saves you money and adds a valuable tool to your garage. Whether you're an experienced mechanic or a weekend warrior, having an engine hoist can make engine repairs, swaps, or maintenance much easier and safer. This guide will walk you through the steps to build a sturdy and reliable engine hoist.

What Will I Get Out of This?

By following this guide, you will learn how to construct an engine hoist that can safely lift engines out of vehicles. This project addresses the problem of expensive commercial options and the need for a customizable hoist that fits your specific workspace and lifting requirements.

Materials and Their Purpose

- Steel Tubing: Forms the frame of the hoist. Steel is chosen for its strength and durability.

- Welding Equipment: To securely join the steel parts. Welding provides the strongest bonds for safety.

- Heavy-Duty Casters: For mobility. Enables you to move the hoist around the garage or workspace.

- Hydraulic Jack: Acts as the lifting mechanism. A hydraulic jack is recommended for its lifting power and reliability.

- Chain and Hook: To secure and lift the engine. Ensure these are rated for the weight of the engine you intend to lift.

- Bolts and Nuts: For assembling non-welded parts and adjustments.

Step-by-Step Instructions

1. Design the Frame

Sketch your design considering the dimensions of your workspace and the typical size of engines you'll work with. The design should include a base, vertical post, and a boom arm.

2. Cut and Prepare Steel Tubing

Measure and cut your steel tubing according to your design. File down any sharp edges for safety.

3. Weld the Frame

Weld the steel pieces together following your design. Start with the base, then the vertical post, and finish with the boom arm. Ensure all welds are strong and clean.

4. Attach the Casters

Bolt the heavy-duty casters to the base. Verify they're securely attached and can handle the full weight of the hoist and engine.

5. Install the Hydraulic Jack

Mount the hydraulic jack to the frame so it pushes against the boom arm. Ensure it's positioned to allow maximum lift and stability.

6. Add the Chain and Hook

Attach a heavy-duty chain and hook to the end of the boom arm. Ensure these components are correctly rated for lifting heavy engines.

7. Test Your Hoist

Perform a safety check. Test the hoist with a weight similar to an engine to ensure stability and proper operation.

Common Pitfalls to Avoid

- Insufficient Welding: Ensure all welds are thorough to prevent failure.

- Underestimating Weight: Use components that can handle more than the engine's weight for extra safety.

- Ignoring Stability: The base should be wide enough to prevent tipping.

Troubleshooting

- Hoist Wobbling: Reinforce the base or adjust the caster placement.

- Insufficient Lifting Power: Check the hydraulic jack's fluid level and ensure it's properly rated for the intended loads.

Expanding the Scope

Consider adding adjustable or foldable features to your engine hoist for easier storage. Additionally, you could add a leveling mechanism to the boom arm for more precise control over the engine's positioning.

Video Tutorial

Want a visual demonstration? Watch a step-by-step video tutorial on YouTube for building an engine hoist/lift. It provides a clear and easy-to-understand visual walkthrough of the techniques, making it a great companion to this written guide.

By following this guide, you'll not only save money by DIYing your engine hoist but also gain a practical tool that enhances your automotive projects. Whether it's for routine maintenance or full engine swaps, your custom-built engine hoist will be a centerpiece of your garage for years to come.

FAQs About DIY Engine Hoist Guide

Learn all about DIY engine hoist guide, including tips, tricks, and common questions answered. Find everything you need to know in one place!

What materials do I need to build a wooden engine hoist?

To construct a wooden engine hoist, you'll need:

- Two 4x6 A-frame swing set mounts

- One 4x6x10' wooden beam

- Four 4x4x8' pressure-treated legs

- One 2x6x8' treated plank

- Lag bolts and washers

- Ratcheting hoist with chain

These materials will form the structure of your hoist, which can be easily assembled and disassembled as needed.

How do I assemble the engine hoist?

Follow these steps to assemble your engine hoist:

- Insert the 4x6 beam into the A-frame mounts and secure with lag bolts.

- Attach the 4x4 legs to the A-frame mounts.

- Cut the 2x6 plank to fit between the legs for stability and attach with lag bolts.

- Stand the A-frame upright.

- Hang the ratcheting hoist from the beam using a chain or heavy strap, ensuring it's rated for the load.

What safety precautions should I take when using an engine hoist?

Safety is paramount when using an engine hoist. Here are some key rules:

- Always use the hoist on a flat and solid surface.

- Ensure the hoist is suitable for the weight of the engine.

- Avoid standing under the lifted load.

- Use smooth, steady movements to avoid swinging the load.

- Keep bystanders, especially children, away from the lifting area.

How do I maintain my DIY engine hoist?

To keep your engine hoist in good condition:

- Regularly inspect for any signs of wear or damage.

- Oil all moving parts biweekly or monthly to ensure smooth operation.

- Check all bolts and connections for tightness before use.

Can I use a DIY engine hoist for other projects?

Yes, a DIY engine hoist can be versatile. Besides engine lifting, it can be used for moving heavy machinery, garage construction, or even as a yard crane for various lifting tasks. Just make sure the load is within the hoist's capacity.

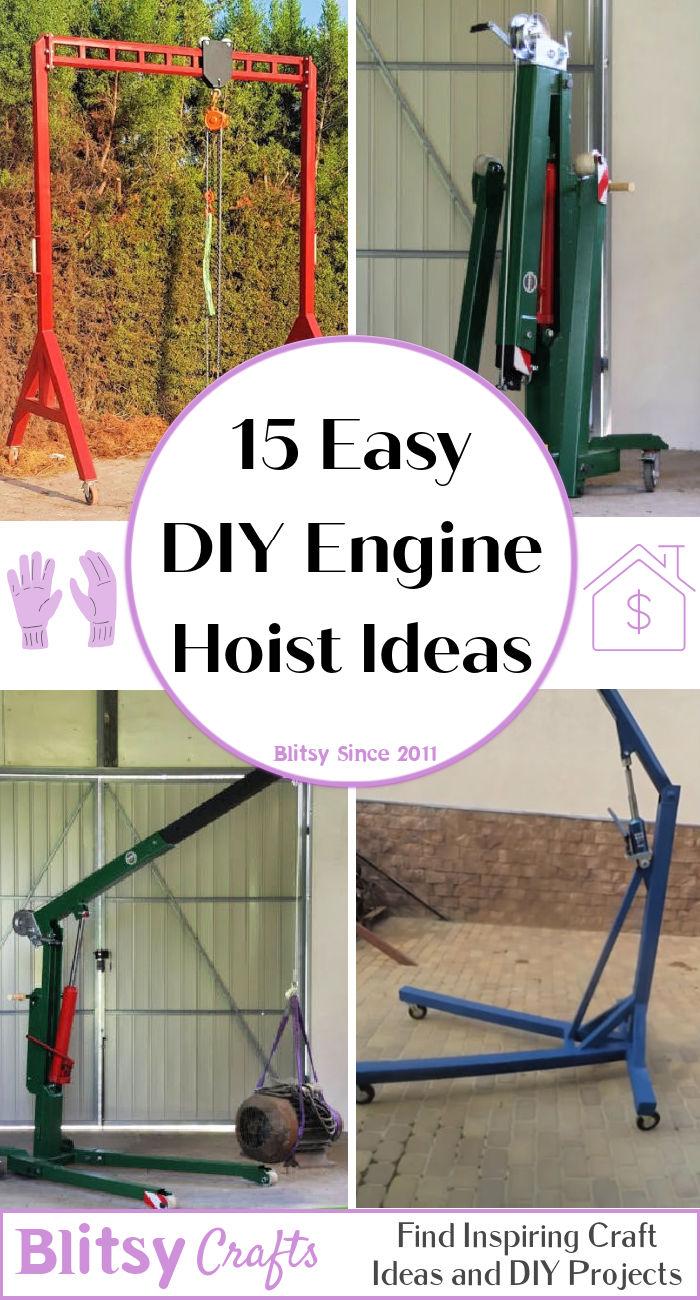

15 DIY Engine Hoist Ideas and Inspirations

Discover 15 practical DIY engine hoist ideas for your next project. From homemade lift systems to innovative designs, get inspired here!

1. How to Build a Hoist Frame at Home

Constructing a hoist frame in your garage brings the convenience of lifting heavy items effortlessly. Aim for a sturdy design that maximizes stability and safety, choosing durable materials capable of withstanding the weight you plan to lift.

2. Free Wooden Engine Hoist Plan

Dive into a woodworking project that's both functional and rewarding. A wooden engine hoist combines traditional craftsmanship with practicality, ideal for occasional, lighter loads. Plus, it's an eco-friendly option that adds a touch of rustic chic to your workspace.

3. Cheap DIY Engine Hoist Frame

Tight on budget? No problem! A DIY engine hoist frame can be crafted with minimal expense. Focus on finding quality, budget-friendly materials, and simple designs. It's the perfect project for those who want functionality without the hefty price tag.

4. Building an Engine Hoist With Winch

Incorporating a winch into your engine hoist design elevates its functionality, allowing for smoother and more controlled lifting. Designing with user safety in mind ensures the winch and frame synergy can handle the intended load securely.

5. DIY Small Mobile Engine Hoist

Perfect for smaller workshops, a DIY mobile engine hoist is a space-saving marvel. Emphasize lightweight materials and compact design so it remains easily maneuverable, while still stout enough to tackle engine lifts with confidence.

6. Homemade Hoist Frame

Fancy a bit of a DIY challenge? Crafting your hoist frame is not only a rewarding project but also tailors perfectly to your specific lifting needs. Focus on robust construction and reliability to build a tool that's as dependable as it is useful.

7. DIY Inexpensive Engine Hoist

Building an engine hoist doesn't need to break the bank. By sourcing cost-effective materials and following straightforward plans, you can assemble a functional hoist that proves efficiency and frugality can go hand in hand.

8. Homemade Hydraulic Engine Hoist

Stepping up the game, a homemade hydraulic engine hoist offers precision lifting, powered by the finesse of hydraulics. It's a project that merges mechanical ingenuity with practical application, destined to be a standout addition to any garage.

9. Easy to Make Engine Hoist for Home Garages

Home garage projects just got easier with this straightforward engine hoist design. Perfect for weekend warriors, it combines simplicity and functionality, turning engine work into a breeze. Enjoy the satisfaction of do-it-yourself mechanics with this handy tool.

10. DIY Lightweight Engine Hoist

Build your very own lightweight engine hoist and say goodbye to back strain. This model's design emphasis is on ease and portability, making it ideal for those with limited space. It's a game-changer for personal garage setups, enhancing your car maintenance experience.

11. Portable DIY Engine Lift

Imagine the convenience of a portable engine lift that you can construct yourself. This design focuses on mobility, allowing you to maneuver around tight spaces effortlessly. It's a brilliant solution for hobbyists who need a flexible lifting option for their diverse projects.

12. Best Portable Engine Hoist

Discover the pinnacle of portable engine hoists, blending robust design with sleek efficiency. It stands out for its durability and user-friendly features, ensuring your engine lifting tasks are smoother and safer. It's the best friend of both seasoned mechanics and beginners alike.

13. How to Make an Engine Hoist Out of Wood

Unlock the potential of your woodworking skills by crafting an engine hoist from wood. It's an eco-friendly and cost-effective solution for those who prefer working with natural materials. This project combines traditional carpentry with mechanical utility, adding a unique touch to your garage.

14. DIY Hilka Engine Hoist Assembly

Dive into a rewarding project with the Hilka engine hoist assembly. This DIY adventure not only sharpens your mechanical skills but also equips your garage with a reliable lifting tool. It's a satisfying endeavor that yields practical results for all your engine work.

15. Installing an Overhead Garage Engine Hoist

Enhance your garage's functionality by installing an overhead engine hoist. It's a fantastic space-saver and adds a professional touch to your work area. This setup allows for efficient use of vertical space, making it easier to maneuver heavy engines without compromising the garage floor area.

Conclusion:

Wrapping up, the DIY engine hoist project is a cost-effective and efficient solution for lifting engines in your garage or workshop. By following the step-by-step guide, you can build your own hoist with basic materials and tools. This project not only saves you money but also provides a practical and customizable option for engine repairs and maintenance. Get started on your DIY engine hoist today!